Table of Contents:

1. Agricultural production identification system based on FPGA

2. Overview of Zynq 7000 FPGA

3. Zynq 7000 FPGA Features

4. Steps of agricultural production identification system

5. MYS-7Z010/20-V2 single board based on Xilinx -7Z010/20 processing

1. Agricultural production identification system based on FPGA

The use of agricultural picking robots has gradually emerged as a new trend in smart agriculture with the advancement of agricultural production methods and vision technology. Automatic detection and identification of crops through machine vision technology has emerged as one of the key technologies in the design of picking robots, determining the effectiveness of the robot’s picking and the financial viability of the farm. The automatic picking robot based on single-chip technology is currently the most popular on the market, but with the rapid advancement of artificial intelligence, the establishment of neural networks based on a large number of image data training recognition methods has emerged as a new generation of smart agricultural development indispensable under challenging circumstances.

The best way to upgrade agricultural production robots, how to select the primary control chip, FPGA real-time high-speed acquisition function, with ARM end of the high-performance processing system, is undoubtedly to upgrade the robots. Zynq 7000 SoC from Xilinx were used as a controller to finish the machine vision algorithms and create the robot control program. Additionally, the efficiency of selecting is increased by the FPGA’s unique parallel processing capabilities, which can concurrently detect several targets for picking. In the meantime, an optimization method and training can be used to learn whether a piece of fruit is suitable for sorting from the image data. If you want to learn more FPGA series, you can look at Vemeko FPGA to learn FPGA series such as Zynq-7000 SoC, FPGA Spartan-7, Artix-7 FPGA, Virtex-7 FPGAs, Kintex-7 FPGAs, Virtex-6 FPGA, Spartan 6 FPGAs, and so on.

2. Overview of Zynq 7000 FPGA

For great performance per watt and maximum design flexibility, Zynq 7000 devices include dual-core ARM Cortex-A9 processors combined with 28nm Artix 7 or KintexTM 7 based programmable logic. Zynq 7000 devices enable very distinctive designs for a variety of embedded applications, including multi-camera driver assistance systems and 4K2K Ultra-HDTV, and are available with transceivers ranging from 6.25Gb/s to 12.5Gb/s. Zynq 7000 FPGA can be applied to ADAS, Medical Endoscope, Small Cell Baseband, Professional Cameras, Machine Vision, Carrier

Ethernet Backhaul, Multi-function Printers.

3. Zynq 7000 FPGA Features

- Integration delivering the de facto programmable platform

- System level performance through optimized architecture

- Architected to deliver low system power

- Most flexible & scalable platform for maximum reuse and best TTM

- Industry-leading design tools, C/C++, and Open CL design abstractions

- Large portfolio of SW & HW design tools, SOMs, design kits, and reference designs

- Innovative ARM® + FPGA architecture for differentiation, analytics & control

- Extensive OS, middleware, stacks, accelerators, and IP ecosystem

- Multiple levels of hardware and software security

4. Steps of agricultural production identification system:

(1) The camera captures the image and sends the image information to the FPGA through the serial port to pre-process the image data.

(2) Call the recognition algorithm program package of ZYNQ chip to recognize the type, maturity, size and other related information of the agricultural products.

(3)Display the corresponding produce information on the touch screen and the cloud through the network and multimedia interface to monitor the screen in real time and record the picking information.

(4) Under the coordination of FPGA and software, calculate the fruit coordinate information in the image, control the motor to run the robotic arm to pick the ripe fruits.

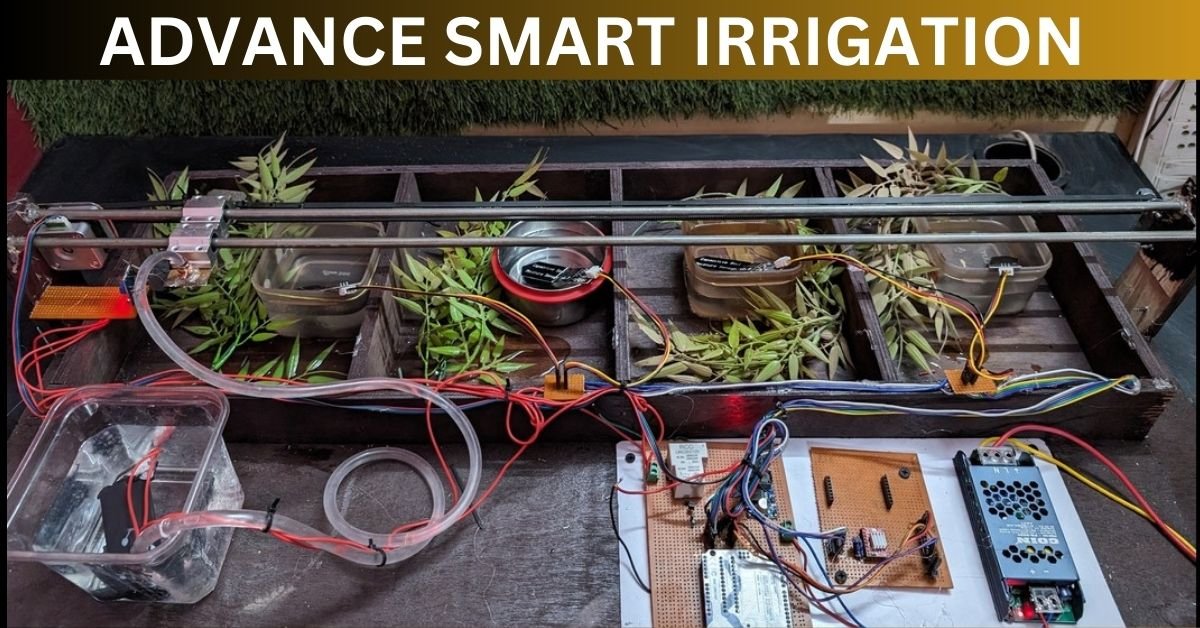

With the increasing demand for hardware for agricultural upgrading, Mir Electronics designed a simple and easy-to-develop single board Z-turn Board based on Xilinx Zynq 7000 series 7Z010/7Z020 processor, with high-capacity storage design to support long-term data storage of the system; it has a rich set of interfaces, such as camera interface, HDMI display interface, and LCD interface, which can be connected with High-definition touch screen, display all kinds of data information, realize in situ monitoring and real-time management of crops; with Gigabit network port and CAN, PMOD, rich I/O and other data communication interfaces, can easily deal with various scenarios under a variety of functional requirements. And the single board supports PYNQ design platform, designers can use Python language and libraries to quickly build more powerful embedded systems by taking advantage of the integration of programmable logic and microprocessor in Zynq.

5. MYS-7Z010/20-V2 single board based on Xilinx -7Z010/20 processing:

SOC: Xilinx Zynq-7010/20 High Performance Dual-Core ARM Cortex-A9 Processing System (PS), FPGA Architecture: Programmable Logic Cell XC7Z010 (28K, about 430,000 logic gates) XC7Z020 (85K, about 1.3M logic gates).

System memory: 1GB DDR3 SDRAM (512MB*2)

Storage: QSPI default 16MB, TF CARD slot (support external boot)

Network: One Gigabit Ethernet port

Video: HDMI port

USB: USB HOST*2

JTAG: 1-way PS/PL multiplexed JTAG interface (for programming debugging download)

Power supply: 5V/0.5A